Making A Box Joint Jig

A box joint jig is not a new idea. Once the jig is built youll need to tweak it for perfectly fitting box.

In all likelihood you have enough scrap in your shop right now to build it.

Making a box joint jig. Rocklers Box Joint Jig has a 12-thick MDF base thats positioned over the router bit on a router table then locked in place using two 38 x 34 metal miter slot bars and star knobs. Quick and easy and you dont need a dado stack. Cut the inverse sockets Flip the first board to the other side of the peg so the reference pin is between the peg and the blade.

They can be built on the table saw with a simple jig made from remnants from your scrap pile. An interesting point that the box joint is stronger than the dovetail joint and does not require the custom dovetail jig. All you need are some miter gauges plywood and careful measuring to get started.

Box joints are a simple economic way to produce a strong joint. It has been around for a long time and a simple plan to build one can be found on the Internet. Make sure your stock is flat and square.

Make sure the miter slot on your router table is within 4-12 to 6-38 from the center of the router bit. Step by step tutorial that can be used on any table sawDetails and. Our shop-made table saw box joint jig is simple to make and easy to use.

The box joint is an alternative to the more popular dovetail joint. If playback doesnt begin shortly try. Dec 28 2019 - Take your woodworking to the next level with this simple box joint jig.

Also make sure opposing sides are identical in length. Make an Accurate Box Joint Jig Simple and Fast. Cut the sides of the box 132 to 116 longer than necessary.

How To Make A Box Joint Jig - YouTube. Push the edges together and make the rest of the cuts. Using this tool will make those cuts clean and efficient.

Make an Accurate Box Joint Jig Simple and Fast - YouTube. Our plans provide you with everything you need to know about how to make a box joint jig. Here is a simple jig for making box joints on your table sawThanks to Per Almered who created the brilliant Handy Woodworking Tip Time jingle for this serie.

A jig is needed to easily cut 12 fingers and equally sized spaces in the end of a board. How to make a finger jointbox joint jig. More or less span will exceed the bases range of adjustability.

It is also important that the width of all sides is identical. How To Make A Box Joint Jig.

How To Make The Perfect Box Joint Jig Finger Joint Jig Beginner Woodworking Diy Youtube

How To Make The Perfect Box Joint Jig Finger Joint Jig Beginner Woodworking Diy Youtube

Box Joint Jig Handles Drawer Joinery With Ease Box Joint Jig Woodworking Box Woodworking Jigs

Box Joint Jig Handles Drawer Joinery With Ease Box Joint Jig Woodworking Box Woodworking Jigs

Box Joint Jig Review How To Make Box Joints Woodworking Jigs

Box Joint Jig Review How To Make Box Joints Woodworking Jigs

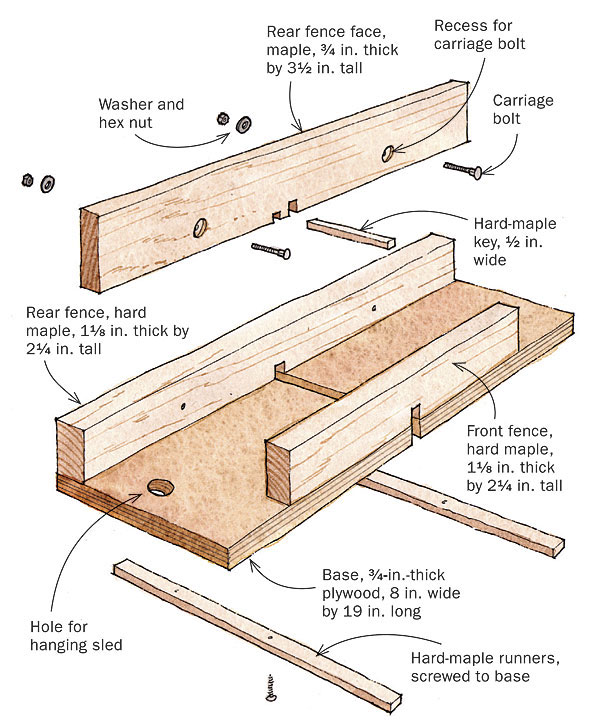

Dedicated Sled Makes The Perfect Finger Joint Jig Free Plans

Dedicated Sled Makes The Perfect Finger Joint Jig Free Plans

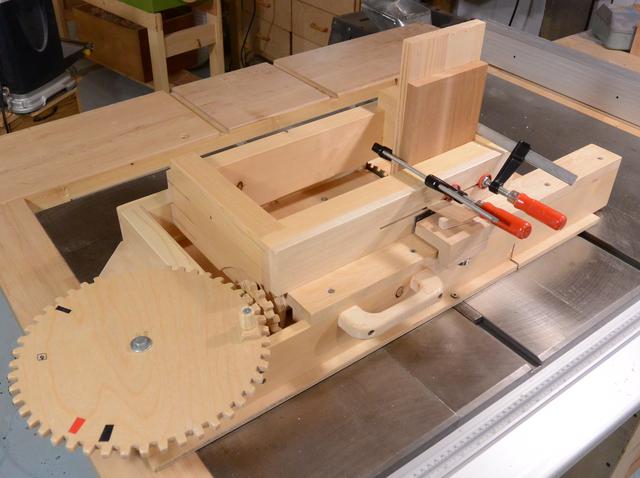

Building An Adjustable Box Joint Jig Scroll Saw Woodworking Crafts

Building An Adjustable Box Joint Jig Scroll Saw Woodworking Crafts

Box Joint Jig Woodworking Project Woodsmith Plans

Box Joint Jig Woodworking Project Woodsmith Plans

Leigh Box Joint Jig Lee Valley Tools

Leigh Box Joint Jig Lee Valley Tools

Box Finger Joint Jig 9 Steps With Pictures Instructables

Box Finger Joint Jig 9 Steps With Pictures Instructables

Adjustable Box Joint Jig Woodworking Project Woodsmith Plans

Adjustable Box Joint Jig Woodworking Project Woodsmith Plans

30 Box Joint Jigs Boxes Ideas Box Joints Box Joint Jig Woodworking Jigs

30 Box Joint Jigs Boxes Ideas Box Joints Box Joint Jig Woodworking Jigs

Single Blade Box Joint Jig Plans

Simple Box Joint Jig For The Router Table Youtube

Simple Box Joint Jig For The Router Table Youtube

Comments

Post a Comment